沸石转轮浓缩技术zeolite rotor concentration principle

工艺原理 / process characteristics◆ voc 浓缩装置可以非常有效的净化和浓缩含有 vocs 的气体,通过和氧化装置或者回收装置组合可以极大降低 voc的处置成本。尤其对于大风量,低浓度的气体。

◆ voc 浓缩转轮使用各种疏水性分子大量浸制到蜂窝陶瓷中,再经过高温焙烧生成。浓缩转轮被密封分为:处理区,再生区以及冷却区三个区域 。整个转轮由一个齿轮马达驱动。

◆ 含有 voc 的被处理空气(通常需要前置过滤)被送到浓缩装轮处理区,在处理区 voc 被吸附后,经过净化的气体从处理区排入烟囱。

◆ 转轮的脱附区邻近处理区。浓缩的 voc可以用少量的高温脱附风脱附出来,从而达到浓缩的效果(浓缩倍率:5-20 倍),然后进入后处理装置。

◆ 脱附后的转轮进入冷却区进行冷却。冷却风可以是一小部分待处理的含 voc的气体,这部分气体可以进入换热器或者加热器加热成为脱附风。

the desorbed part of the rotor is further rotated to the cooling zone, where the zone is cooled by the cooling gas. a part of voc laden exhaust gas from the factory passes through the cooling zone and is

transferred to a heat exchanger or a heater to be heated and utilized as desorption air.

voc concentration rotor is made of honeycomb inorganic paper as a substrate, in which the high-silica zeolite (molecular sieve) is impregnated. the rotor is divided into 3 zones such as process, desorption and

cooling zones by the casing structure and heat resistance air sealing. the rotor is constantly rotated at the optimum rotation speed by a geared motor.

voc laden exhaust gas passes through the process zone of the rotor being continuously rotated, and the incombustible zeolite in the rotor adsorbs vocs and exhausts purified gas to the ambient.

voc adsorbed part of the rotor is rotated to the desorption zone, where the adsorbed vocs can be desorbed with small amount of high temperature desorption air and be concentrated to the high concentration

level (5 to 20 times). then, the high concentrated voc gas is transferred to appropriate post treatment systems such as incinerators or recovery systems.

the desorbed part of the rotor is further rotated to the cooling zone, where the zone is cooled by the cooling gas. a part of voc laden exhaust gas from the factory passes through the cooling zone and is transferred

to a heat exchanger or a heater to be heated and utilized as desorption air.

技术优势 / process characteristics

高效能 • 高效率 / high performance & efficiency将吸附性能极好的疏水性分子筛作为吸附剂使用,对于广泛的 voc 种类,不同的运转条件,都可以提供卓越的性能using high silica zeolites with enormous adsorption capacity allows our voc concentrator to flexibly treat various kinds of vocs and work under different conditions of operation.

高沸点的溶剂处理 / capability of treating vocs with high boiling point用活性炭时因为有再生温度的限制而无法处理高沸点的 voc, 对于使用疏水性的分之筛时,可以利用其不燃性。高耐热性的特点可以在高温条件下再生,从而得以处理carbon material has a difficulty to treat vocs with high boiling point due to its desorption temperature limit. in contrast, the characteristics of our zeolite rotors are incombustible and high heat resistance, which enables

our voc concentrator to use the adsorption air with high temperature.

惰性 / inertness即使是苯乙烯和环己酮等具有热聚性高的 voc, 也能使用疏水性的分子筛高效处理voc easily polymerized by heat energy (e.g. st yrene, cyclohexanone, etc) can be effectively treated by high-silica zeolite.

清洗和活化 / cleanability & activation by special heat treatment心脏部分的浓缩装轮因为在高温下烧结处理而成,完全是无机的结合体。如果发生蜂窝堵塞,可以进行水洗。另外,分子筛转轮可以根据实际情况通过高温活化our zeolite rotors through calcining process have come to all inorganic material including the adhesive. clogging in the rotor element might occur after a certain period of use. but, don’t worry!!

the rotor is washable in a proper manner to remove accumulated dust. it’s even better that our zeolite rotor can be reactivated by heat treatment according to circumstances.

典型应用 / process characteristics宗亚的工程师随时待命和你探讨你的具体案例,几个重要因数对于转轮的设计选型非常重要,这些因数包含流量,温度,相对湿度,voc 组分以及浓度。

以下是一个非常典型应用:

催化氧化/蓄热式催化氧化 (cto/rco)

recovery of solvent type

工艺原理 / process characteristics

直接热力学氧化法是在高温条件下,将vocs直接氧化为co2和h2o(g)的过程,并利用多通道换热器回收热量,去除效率达99.9%。directive thermal oxidizer (to) converts vocs into carbon dioxide and water vapor, using multi-channel heat exchanger to recover heat, with removal efficiency of 99.9%.技术优势 / process characteristics

■ 废气净化效率高:vocs去除效率达99.9%■ 充分回收热能:采用余热回收装置,热效率≥75%■ 无二次污染产生(nox、二噁英)■ 直接利用废气中氧气助燃,无需额外补充新鲜空气high cleaning efficiency, > 99.9%very high thermal efficiency, ≥75%no formation of secondary products (nox, dioxin)no extra fresh air: make use of the oxygen of process stream directly适用特征 / process characteristics

■ 高vocs浓度:2500~4500ppm■ 处理一种或多种组分的高浓度vocs,异味气体、氟利昂及各种含卤素、氨气的气体■ 废气流量100~150000nm3/hhigh vocs concentration: 2500~4500ppmtreatment of one or more components of vocsexhaust air volume:100~150000nm3/hs

蓄热式热力学氧化/rto

recovery of solvent type

工艺原理 / process characteristics

采用多床固定式或旋转式蓄热室和燃烧室,经预热后的有机废气燃烧室高温氧化分解,净化后的高温尾气经蓄热体降温后达标排放,蓄热体预热进口废气,节省能源。设备运行温度800℃左右。directive thermal oxidizer (to) converts vocs into carbon dioxide and water vapor, using multi-channel heat exchanger to recover heat, with removal efficiency of 99.9%.

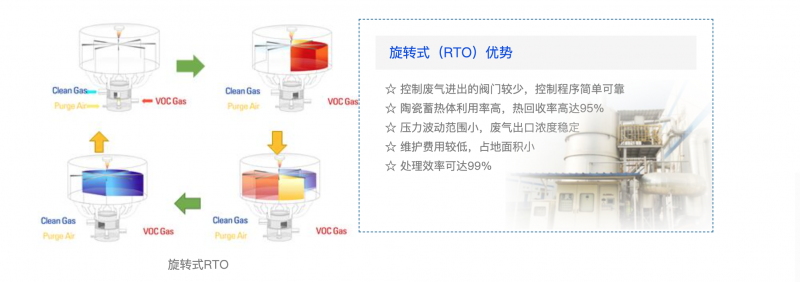

旋转式rto在塔式rto的基础上进一步提高了vocs的去除效率和热回收效率,并减少rto启动的能源消耗,同时,解决了塔式rto在阀门切换时逸散vocs直接排入烟囱等问题。

技术优势 / process characteristics

■ 废气净化效率高:vocs去除效率≥95%■ 充分回收热能:热回用率≥90%■ 无二次污染产生(nox、二噁英)■ 低能耗in the exhaust gas purification efficiency: vocs removal efficiency is more than 95%in the full recovery of energy: heat reuse rate greater than 90%no two pollution (nox, dioxins)low power consumption典型应用/ process characteristics

■ 中、高vocs浓度:250~2500ppm■ 处理一种或多种组分vocs■ 废气流量1000~100000nm3/hhin the middle and high concentration of vocs: 250 ~ 2500ppmin the processing of one or more components of vocsin the exhaust gas flow 1000~100000nm3/h

技术优势 / process characteristics

■ 废气净化效率高:vocs去除效率≥95%■ 充分回收热能:热回用率≥90%■ 无二次污染产生(nox、二噁英)■ 低能耗in the exhaust gas purification efficiency: vocs removal efficiency is more than 95%in the full recovery of energy: heat reuse rate greater than 90%no two pollution (nox, dioxins)low power consumption典型应用/ process characteristics

■ 中、高vocs浓度:250~2500ppm■ 处理一种或多种组分vocs■ 废气流量1000~100000nm3/hhin the middle and high concentration of vocs: 250 ~ 2500ppmin the processing of one or more components of vocsin the exhaust gas flow 1000~100000nm3/h

官方公众号

官方公众号 官方小程序

官方小程序

发表用户评论,可得5积分,积分可兑换“100元天猫卡”等实物好礼;更有机会成为“星级评价官”,享受专属权益,快来积极参与吧!

共0条